Production Description:

Standard:ASTM A335

Grade:SA335 P5、SA335 P11、SA335 P12、SA335P22、SA335 P91、SA335 P92

Lead Condition:Hot Rolling

Size Range:OD 219MM-1066MM ,Thickness 6MM-120MM

Tolerance:According to ASTM A335

Length:As request

| Standard | Grade | Chemical Compostion(%) | |||||||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Ni | V | Al | W | Nb | N | ||

| ASME SA335 | SA335 P11 | 0.05~0.15 | 0.50~1.0 | 0.30~0.60 | ≤0.030 | ≤0.030 | 1.00~1.50 | 0.50~1.00 | |||||||

| SA335 P12 | 0.05~0.15 | ≤0.50 | 0.30~0.61 | ≤0.030 | ≤0.030 | 0.80~1.25 | 0.44~0.65 | ||||||||

| SA335 P22 | 0.05~0.15 | ≤0.50 | 0.30~0.60 | ≤0.030 | ≤0.030 | 1.90~2.60 | 0.87~1.13 | ||||||||

| SA335 P5 | ≤0.15 | ≤0.50 | 0.30~0.60 | ≤0.030 | ≤0.030 | 4.00/6.00 | 0.45/0.65 | ||||||||

| SA335 P91 | 0.08~0.12 | 0.20~0.50 | 0.30~0.60 | ≤0.020 | ≤0.010 | 8.00~9.50 | 0.85~1.05 | ≤0.40 | 0.18~0.25 | ≤0.015 | 0.06~ 0.10 | 0.03~ 0.07 | |||

| SA335 P92 | 0.07~0.13 | ≤0.50 | 0.30~0.60 | ≤0.020 | ≤0.010 | 8.50~9.50 | 0.30~0.60 | 0.30~0.60 | ≤0.40 | 0.15~0.25 | ≤0.015 | 1.50~2.00 | 0.04~ 0.09 | 0.03~ 0.07 | |

| Standard | Grade | Mechanical Properties | ||

| Yield Strength | Tensile Strength | Elongation | ||

| ASME SA335 | SA335 P11 | ≥415 | ≥220 | ≥22 |

| SA335 P12 | ≥415 | ≥220 | ≥22 | |

| SA335 P22 | ≥415 | ≥205 | ≥22 | |

| SA335 P5 | ≥415 | ≥205 | ≥22 | |

| SA335 P91 | 585~760 | ≥415 | ≥20 | |

| SA335 P92 | ≥620 | ≥440 | ≥20 | |

| Product name | Material | Standard | Size(mm) | Application |

| Low temperature tube | 16MnDG 10MnDG 09DG 09Mn2VDG 06Ni3MoDG ASTM A333 | GB/T18984-2003 ASTM A333 | OD:8-1240*WT:1-200 | Apply to - 45 ℃ ~ 195 ℃ low temperature pressure vessel and low temperature heat exchanger pipe |

| High-pressure boiler tube | 20G ASTMA106B ASTMA210A ST45.8-III | GB5310-1995 ASTM SA106 ASTM SA210 DIN17175-79 | OD:8-1240*WT:1-200 | Suitable for manufacturing high pressure boiler tube, header, steam pipe, etc |

| Petroleum cracking tube | 10 20 | GB9948-2006 | OD: 8-630*WT:1-60 | Used in oil refinery furnace tube, heat exchanger tube |

| Low medium pressure boiler tube | 10# 20# 16Mn,Q345 | GB3087-2008 | OD:8-1240*WT:1-200 | Suitable for manufacturing various structure of low and medium pressure boiler and locomotive boiler |

| General structure of the tube | 10#,20#,45#,27SiMn ASTM A53A,B 16Mn,Q345 | GB/T8162-2008 GB/T17396-1998 ASTM A53 | OD:8-1240*WT:1-200 | Apply to the general structure, engineering support, mechanical processing, etc |

| Oil casing | J55,K55,N80,L80 C90,C95,P110 | API SPEC 5CT ISO11960 | OD:60-508*WT:4.24-16.13 | Used for extraction of oil or gas in oil Wells casing, used in oil and gas well sidewall |

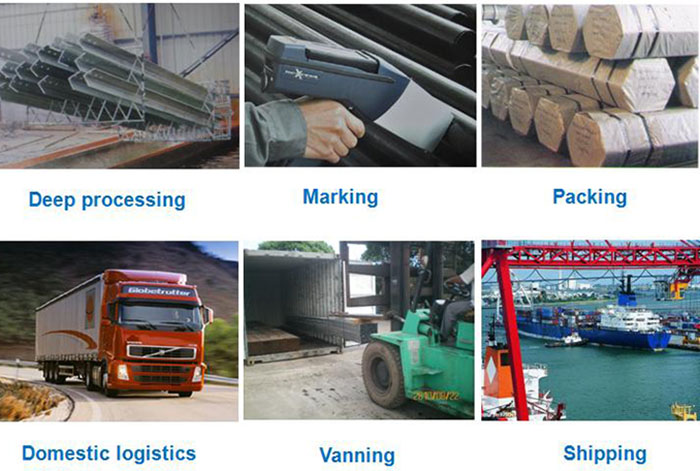

Simple Description: Pipe spools for CCPP under dispatching. Main-Steam and Hot-reheat pipelines in comply with the material codes SA335 P91&A234WP91 in order to withstand the max temperature up to 580℃。 Cold-reheat pipelines adopt the material of SA335 P11/P22&A234 P11/P22 to endure the medium temperature and pressures。 WB36 is the best material option for Water-feeding pipeline with the application to bear the highest pressure(36Mpa). Another signature project of 2*660MW Super-critical Power Plant witness our capacity and achievements. Integral piping material package delivery (Pipes+Fittings+Bends+Flanges/Forging=Pipe Spools), catering for the critical pipeline applications of CCPP,HRSG and Boiler. State of Art craftsmanship along with the numerous know-how and experience to conceptualize the very notion " Diligence,Exact,reliability". Our Service:

Simple Description: Pipe spools for CCPP under dispatching. Main-Steam and Hot-reheat pipelines in comply with the material codes SA335 P91&A234WP91 in order to withstand the max temperature up to 580℃。 Cold-reheat pipelines adopt the material of SA335 P11/P22&A234 P11/P22 to endure the medium temperature and pressures。 WB36 is the best material option for Water-feeding pipeline with the application to bear the highest pressure(36Mpa). Another signature project of 2*660MW Super-critical Power Plant witness our capacity and achievements. Integral piping material package delivery (Pipes+Fittings+Bends+Flanges/Forging=Pipe Spools), catering for the critical pipeline applications of CCPP,HRSG and Boiler. State of Art craftsmanship along with the numerous know-how and experience to conceptualize the very notion " Diligence,Exact,reliability". Our Service:  RFQ: Q1: Are you manufacture or Trader A: We are both manufacture and trader Q2: Can you offer sample? A: Sample small one can be offered by free, but buyer should pay the express fee Q3: Can you offer processing service? A: We can offer cutting, drilling, painting, coat powder etc... Q4: What is your advantage on steel? A: We can customize steel structure accoridng to buy's drawings or request. Q5: How about your logistic service? A: we have professional logistic team who has rich experience on shipping, can offer the steady and quality ship line.

RFQ: Q1: Are you manufacture or Trader A: We are both manufacture and trader Q2: Can you offer sample? A: Sample small one can be offered by free, but buyer should pay the express fee Q3: Can you offer processing service? A: We can offer cutting, drilling, painting, coat powder etc... Q4: What is your advantage on steel? A: We can customize steel structure accoridng to buy's drawings or request. Q5: How about your logistic service? A: we have professional logistic team who has rich experience on shipping, can offer the steady and quality ship line.