1. Production Description:

Standard:EN10216-2

Grade:16Mo3

Size Range:φ10~φ209*1~20mm

Tolerance:EN10216-2

Length:As request

MTC:PED, EN 10204/3.1

2. Chemical Compostion:

| Standard | Grade | Chemical Compsition (Max %) | ||||||

| C | Si | Mn | P | S | Cr | Mo | ||

| En10216-2 | 16Mo3 | 0.12-0.2 | ≤0.35 | 0.4-0.9 | ≤0.025 | ≤0.01 | ≤0.30 | 0.25-0.35 |

| Standard | Grade | Tensile Strength | Yield Strength | Elongation |

| (MPa) | (MPa) | (%) | ||

| En10216-2 | 16Mo3 | 440-590 | ≥260 | ≥22 |

5. Application: 1) Standard: EN10028 EN10222-2 2017 (European standard, foreign standard) 2) Naming: It is named according to the content of C (carbon) and Mo (molybdenum), which means that the carbon content of this steel plate is about 160, while the content of molybdenum is about 300. 3) Heat treatment: normalizing or normalizing + tempering 4) 16Mo3 is different from other materials when welding. It must be preheated first, and the weld should be kept warm for about 30 minutes after the welding is completed. 5)16mo3 steel manganese is also an important alloying element in steel and an important hardenability element, which has a great influence on the toughness of the weld metal. 6) When the Mn content of 16mo3 steel plate is less than 0.05%, the toughness of the weld metal is very high; 7) 16mo3 steel plate is very brittle when the Mn content is more than 3%; 8) When the Mn content of 16mo3 steel plate is 0.6-1.8%, TEL: 180-377-99127% weld metal has higher strength and toughness. 9) What effect does sulfur (S) element of 16mo3 steel plate have on weldability? 10) Sulfur often exists in the form of iron sulfide in steel, and is distributed in the grain boundary in a network, thus significantly reducing the toughness of steel. The eutectic temperature of iron plus iron sulfide is low (985°C). Therefore, during hot processing, the starting temperature of processing is generally 1150-1200°C, and the eutectic of iron and iron sulfide has melted, resulting in cracking during processing. This phenomenon is the so-called "hot brittleness of sulfur". This property of sulfur causes steel to develop hot cracks when welded. Therefore, the content of sulfur in steel is generally strictly controlled. The main difference between ordinary carbon steel, high-quality carbon steel and high-quality high-quality steel is the content of sulfur and phosphorus. 6. Related Pipe Production list:

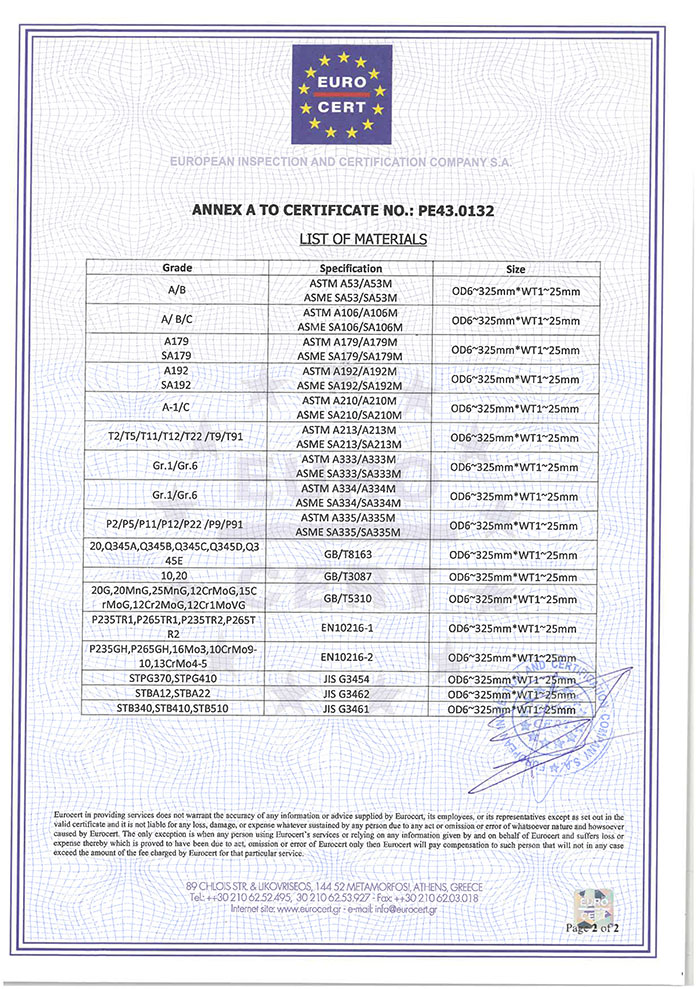

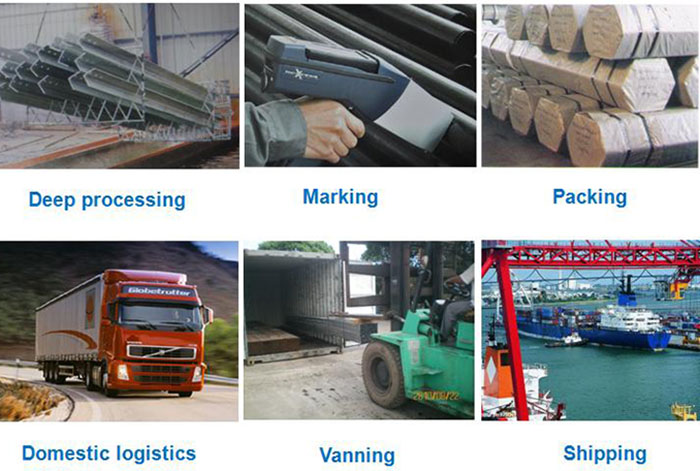

5. Application: 1) Standard: EN10028 EN10222-2 2017 (European standard, foreign standard) 2) Naming: It is named according to the content of C (carbon) and Mo (molybdenum), which means that the carbon content of this steel plate is about 160, while the content of molybdenum is about 300. 3) Heat treatment: normalizing or normalizing + tempering 4) 16Mo3 is different from other materials when welding. It must be preheated first, and the weld should be kept warm for about 30 minutes after the welding is completed. 5)16mo3 steel manganese is also an important alloying element in steel and an important hardenability element, which has a great influence on the toughness of the weld metal. 6) When the Mn content of 16mo3 steel plate is less than 0.05%, the toughness of the weld metal is very high; 7) 16mo3 steel plate is very brittle when the Mn content is more than 3%; 8) When the Mn content of 16mo3 steel plate is 0.6-1.8%, TEL: 180-377-99127% weld metal has higher strength and toughness. 9) What effect does sulfur (S) element of 16mo3 steel plate have on weldability? 10) Sulfur often exists in the form of iron sulfide in steel, and is distributed in the grain boundary in a network, thus significantly reducing the toughness of steel. The eutectic temperature of iron plus iron sulfide is low (985°C). Therefore, during hot processing, the starting temperature of processing is generally 1150-1200°C, and the eutectic of iron and iron sulfide has melted, resulting in cracking during processing. This phenomenon is the so-called "hot brittleness of sulfur". This property of sulfur causes steel to develop hot cracks when welded. Therefore, the content of sulfur in steel is generally strictly controlled. The main difference between ordinary carbon steel, high-quality carbon steel and high-quality high-quality steel is the content of sulfur and phosphorus. 6. Related Pipe Production list:  7. Our service:

7. Our service:  8. Other Production:

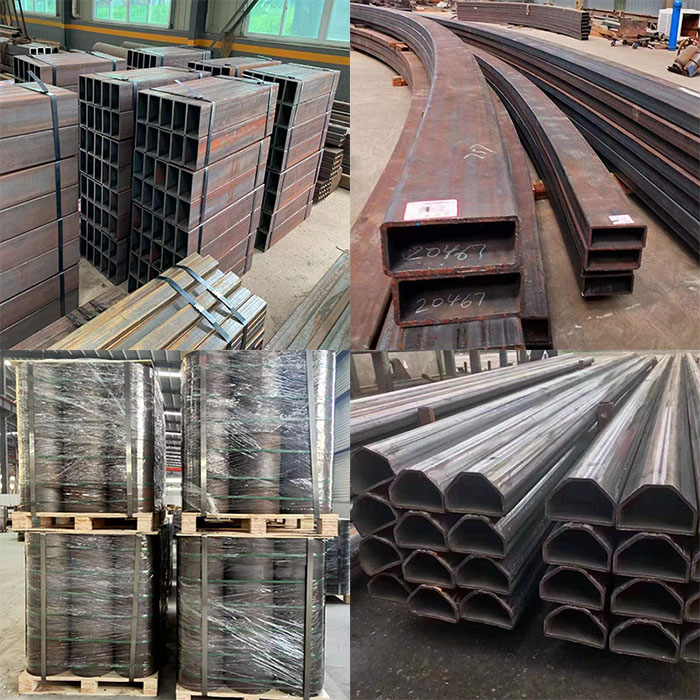

8. Other Production:

9. Contact Person: Roger Zhang Position:Sales Director Email: roger@shhuaxinsteel.com Phone: +86 527 8888 0826 Cell: +86 182 4897 6466 Whatsapp/Wechat:+86 182 4897 6466 Rich Experience on Stainless and Carbon Steel tube, fittings, Steel Structure project ETC.

9. Contact Person: Roger Zhang Position:Sales Director Email: roger@shhuaxinsteel.com Phone: +86 527 8888 0826 Cell: +86 182 4897 6466 Whatsapp/Wechat:+86 182 4897 6466 Rich Experience on Stainless and Carbon Steel tube, fittings, Steel Structure project ETC.